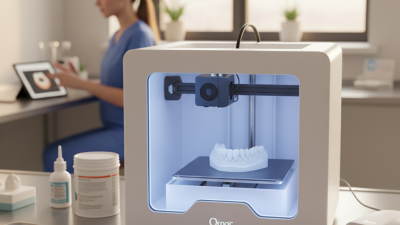

As we look towards the future of 3D printing technology, the advancements in SLA printers are paving the way for exceptional printing results in various industries. Among the leaders in this field is the Anycubic SLA 3D Printer, known for its precision and reliability. According to Dr. Sarah Thompson, a leading expert in additive manufacturing, "In 2025, the integration of advanced software and improved resin materials will revolutionize the accuracy and detail achievable in 3D prints." Her insights point to a future where the capabilities of SLA printers are expanded significantly.

The growing demand for high-quality prints has driven innovation in SLA technology, with features like faster printing speeds, enhanced user interfaces, and smarter calibration processes. These advancements promise not only to improve user experience but also to elevate the quality and consistency of finished products. With the evolution of the Anycubic SLA 3D Printer, we can expect a transformative shift in how creators and engineers approach their projects, enabling them to bring their visions to life with unprecedented precision.

As we explore the top features of SLA 3D printers in 2025, it is essential to consider how these changes will impact various sectors such as prototyping, art, and manufacturing. The Anycubic SLA 3D Printer stands at the forefront of this evolution, ready to meet the needs of users seeking perfection in their prints.

The landscape of SLA 3D printing is set to transform significantly by 2025, driven by a slew of technological innovations aimed at enhancing the quality and efficiency of prints. One key advancement is the introduction of advanced resin materials that not only reduce curing times but also improve the mechanical properties of the finished products.

Reports from industry analysts predict that by 2025, the adoption of high-performance resins, such as those engineered for increased durability and temperature resistance, will grow by more than 50%, enabling applications in demanding sectors like aerospace and medical.

In addition to enhanced materials, the integration of Artificial Intelligence (AI) and machine learning into SLA 3D printing workflows is expected to optimize the printing process considerably. These technologies will facilitate real-time monitoring and adjustments, ensuring consistency in print quality and significantly reducing waste. Studies suggest that AI-driven automation can decrease production time by up to 30%, paving the way for more efficient scaling of 3D production in various industries. As manufacturers continue to invest in these innovations, the future of SLA 3D printing looks promising, setting new standards for precision and reliability.

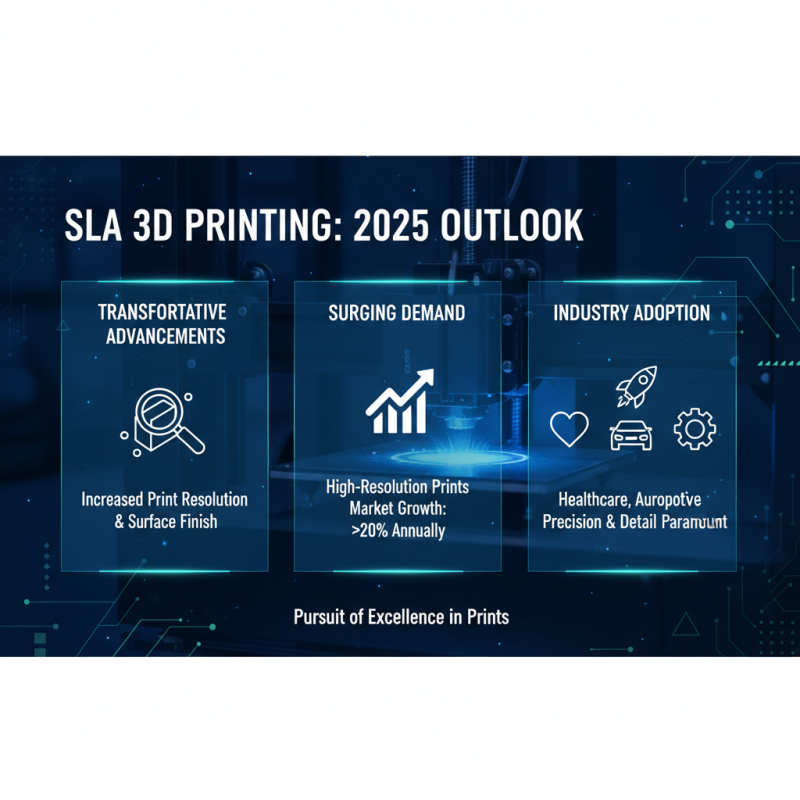

As we move into 2025, the SLA 3D printing landscape is set to witness transformative advancements in print resolution and surface finish. Recent industry reports indicate that the demand for high-resolution prints is surging, with a projected market growth of over 20% annually for the next few years. This relentless pursuit of excellence in prints is attributed to the evolving needs of industries such as healthcare, aerospace, and automotive, where precision and detail are paramount.

Enhanced print resolution in SLA printers will allow for layer thickness reductions down to 25 microns or even lower, which significantly diminishes the visibility of layer lines, leading to smoother and more intricate designs. This capability is driven by advancements in laser technology and optics, coupled with the development of higher-quality resin materials. Surface finishes are also expected to reach new heights, with innovations in post-processing techniques enabling users to achieve mirror-like surfaces more efficiently—essential for applications where aesthetics are just as crucial as functionality.

Furthermore, reports suggest that the next generation of SLA printers will incorporate AI-driven features that analyze print parameters in real-time, optimizing settings to enhance both resolution and surface quality. As these technologies mature, the increasing accessibility of SLA printing will empower more creators and industries to produce exceptional quality prints, reshaping what is possible in additive manufacturing.

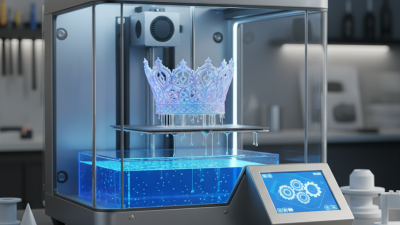

In 2025, the landscape of SLA 3D printing is set to undergo a significant transformation, especially concerning material compatibility. As industries increasingly demand versatility in applications, manufacturers are responding with advanced resin formulations that cater to a broader range of use cases. Recent industry reports highlight that the SLA 3D printing market is projected to grow by 25% annually, driven by innovations in materials that offer enhanced strength, flexibility, and heat resistance, making them suitable for sectors like aerospace, automotive, and healthcare.

One notable trend is the rise of biocompatible resins, which are crucial for medical applications where safety and efficacy are paramount. Data suggests that over 40% of professionals in the medical field are now utilizing SLA 3D printing for prototyping and producing custom implants, demonstrating the technology's potential in creating personalized healthcare solutions. Additionally, the development of eco-friendly materials resonates with the growing sustainability movement, enabling manufacturers to create products that meet environmental standards without sacrificing performance.

Tips: When selecting SLA 3D printing materials, always consider the specific requirements of your project. Compatibility with your printer and the desired properties of the final product should guide your material choice. Moreover, stay updated on advancements in materials science, as new formulations may provide unexpected advantages for your applications. Embracing diverse material options can enhance creativity and innovation in design, leading to superior outcomes in your projects.

The evolution of SLA 3D printers in 2025 places a strong emphasis on user-friendly interfaces and seamless software integration. As the demand for high-quality prints continues to rise, manufacturers are prioritizing intuitive controls that allow users of all skill levels to operate their machines with confidence.

Touchscreen displays with customizable layouts provide easy navigation through various settings, reducing the learning curve for beginners while enhancing efficiency for experienced users. Additionally, tools such as guided printing processes and real-time monitoring contribute to an overall better user experience.

Software features are also advancing rapidly, with enhanced design compatibility and streamlined workflows. Modern SLA printers now come equipped with software that automates critical tasks such as model slicing and supports generation, enabling users to focus more on creativity rather than technical hurdles. Cloud connectivity allows for easy upload and management of print jobs, ensuring that users can work from anywhere.

Moreover, integrated troubleshooting tools can diagnose issues quickly, minimizing downtime and maintaining productivity. This combination of user-friendly interfaces and sophisticated software functionalities makes SLA 3D printing more accessible and efficient than ever before.

In recent years, sustainability has emerged as a crucial consideration in the realm of 3D printing, particularly in SLA (Stereolithography) technologies. As industries shift towards more eco-friendly practices, the implementation of sustainable materials and processes in SLA 3D printing has gained momentum. According to a 2023 report by the Industry Research Group, approximately 60% of SLA printer manufacturers are now prioritizing recyclable and bio-based resins in their product offerings. These innovations not only reduce waste but also significantly lower the carbon footprint associated with traditional manufacturing methods.

Moreover, advancements in clean energy technologies are reshaping the SLA 3D printing landscape. The integration of renewable energy sources in production facilities, as highlighted by the Global Sustainability Institute, has been shown to decrease energy consumption by up to 40% in SLA operations. As companies strive to meet rigorous sustainability targets, the incorporation of eco-friendly practices throughout the supply chain—from sourcing materials to energy-efficient printing processes—becomes imperative. This holistic approach not only satisfies consumer demands for sustainable products but also positions companies as leaders in the transition towards a greener manufacturing framework.