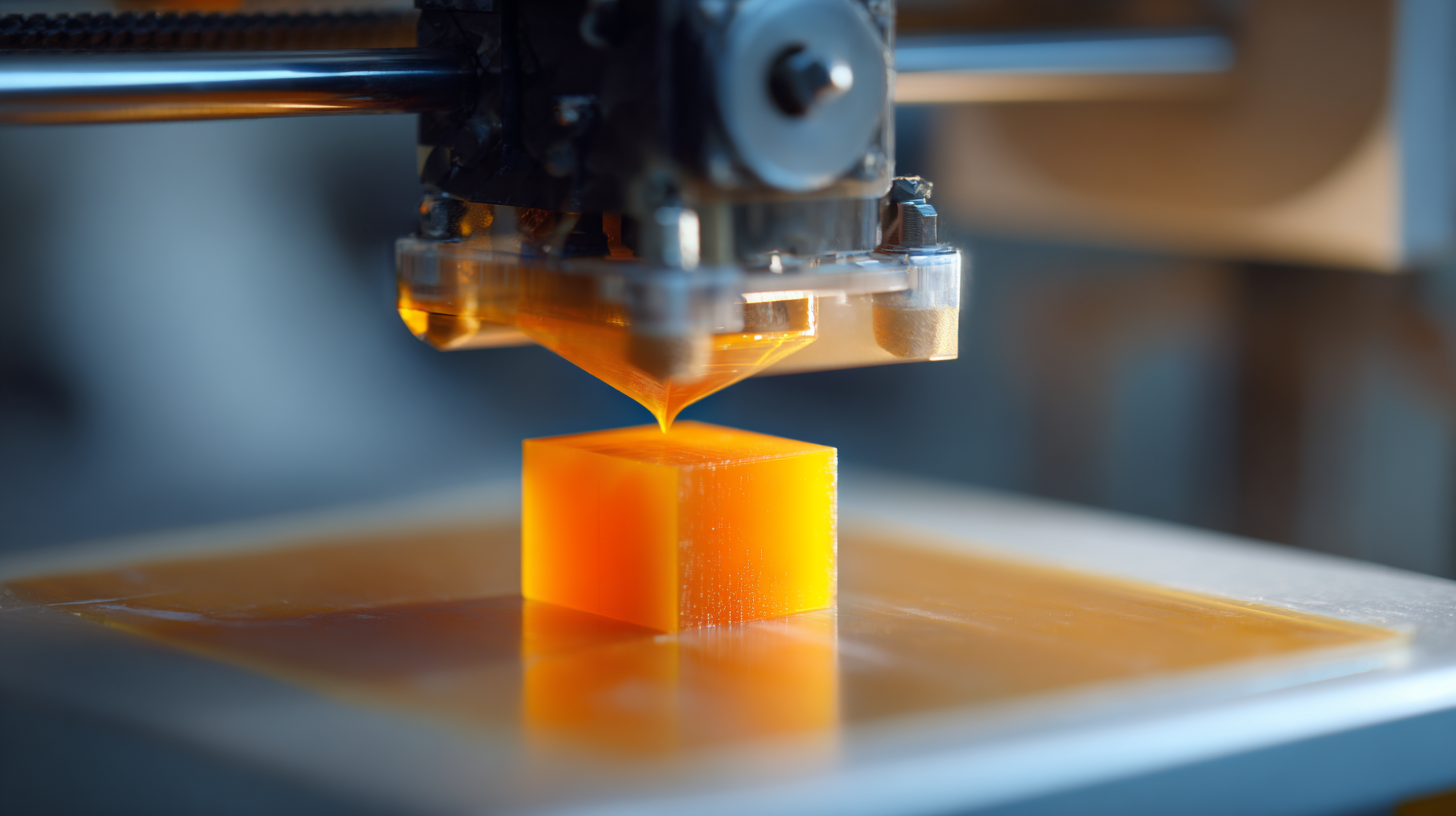

When embarking on 3D printing projects, one of the most critical components to consider is the type of resin used, particularly when striving for precision and detail. High Wax Resin for 3D Printer applications has gained immense popularity among enthusiasts and professionals alike due to its unique properties that facilitate the production of intricate designs. Its waxy composition allows for finer details and smoother finishes, making it an ideal choice for creating detailed models, prototypes, and even jewelry.

In this guide, we will delve into the essential factors to consider when choosing the best High Wax Resin for 3D Printer needs. With a plethora of options available on the market, understanding the specific qualities such as curing time, compatibility with printers, and finish quality is crucial. We will also present our "Top 10" recommendations, providing insights into each product’s performance and suitability for various projects. Whether you are a hobbyist looking to enhance your work or a professional seeking optimal results, this comprehensive overview aims to equip you with the knowledge necessary to make an informed decision.

High wax resin is an innovative material tailored for 3D printing, particularly suited for projects requiring intricate detail and smooth finishes. Unlike standard resins, high wax resins are specifically formulated with wax additives that enhance their fluidity and give them unique properties that facilitate the creation of complex geometries. This makes them ideal for applications in jewelry making, dental models, and other detailed projects where precision is paramount.

One of the primary advantages of high wax resin is its ability to produce exceptionally fine details without compromising the structure of the print. The wax component allows for easier removal from molds and supports, resulting in a cleaner final product. Additionally, high wax resins typically exhibit lower shrinkage during the curing process, which maintains dimensional accuracy and avoids issues associated with warping or distortion. For 3D printing enthusiasts and professionals looking to achieve superior quality in their projects, understanding the benefits of high wax resin can significantly enhance the overall outcome of their 3D printing endeavors.

When selecting high wax resin for your 3D printer projects, there are several key factors to consider to ensure optimal results. First and foremost, the intended application of your prints plays a significant role in resin selection. For example, if you're creating highly detailed models or jewelry, you will want a resin that offers excellent resolution and a smooth finish. Look for products specifically designed for fine detail work, which typically advertise high viscosity and low shrinkage properties.

**Tips:** Always test a small batch of resin on a sample print before committing to large projects. This will help you gauge color accuracy, finish quality, and compatibility with your printer.

Another factor to consider is the curing time and compatibility with your printer's specifications. Some resins cure faster than others, which can significantly affect your workflow. Make sure to choose a resin that aligns with the printing speed of your machine to avoid layering issues. Additionally, check whether the resin requires specific settings for optimal curing; incorrect parameters can lead to poor adhesion or warping.

**Tips:** Refer to user reviews and technical data sheets for insights into the resin’s performance with your specific printer model.

This chart illustrates key factors to consider when selecting high wax resin for 3D printing projects, including viscosity, curing time, flexural strength, shore hardness, and color variety.

When selecting high wax resin for your 3D printer, it's essential to compare various brands and types to determine which best meets your performance requirements. Different manufacturers offer unique formulations that can influence the properties of your final prints. For instance, some brands may prioritize flexibility and durability, while others focus on precision and detail. Understanding the characteristics of each brand, such as curing time, viscosity, and finish quality, will allow you to make more informed choices tailored to your project needs.

In addition to brand comparisons, exploring the types of high wax resin available is crucial. Some resins feature specialized additives that enhance their performance for specific applications, like jewelry casting or prototyping. Evaluating user reviews and sample prints can provide insights into how these resins behave under various conditions. Factors like post-processing requirements and compatibility with different printing technologies also play a significant role in selecting the right resin for optimal results in your 3D printing endeavors.

In addition to brand comparisons, exploring the types of high wax resin available is crucial. Some resins feature specialized additives that enhance their performance for specific applications, like jewelry casting or prototyping. Evaluating user reviews and sample prints can provide insights into how these resins behave under various conditions. Factors like post-processing requirements and compatibility with different printing technologies also play a significant role in selecting the right resin for optimal results in your 3D printing endeavors.

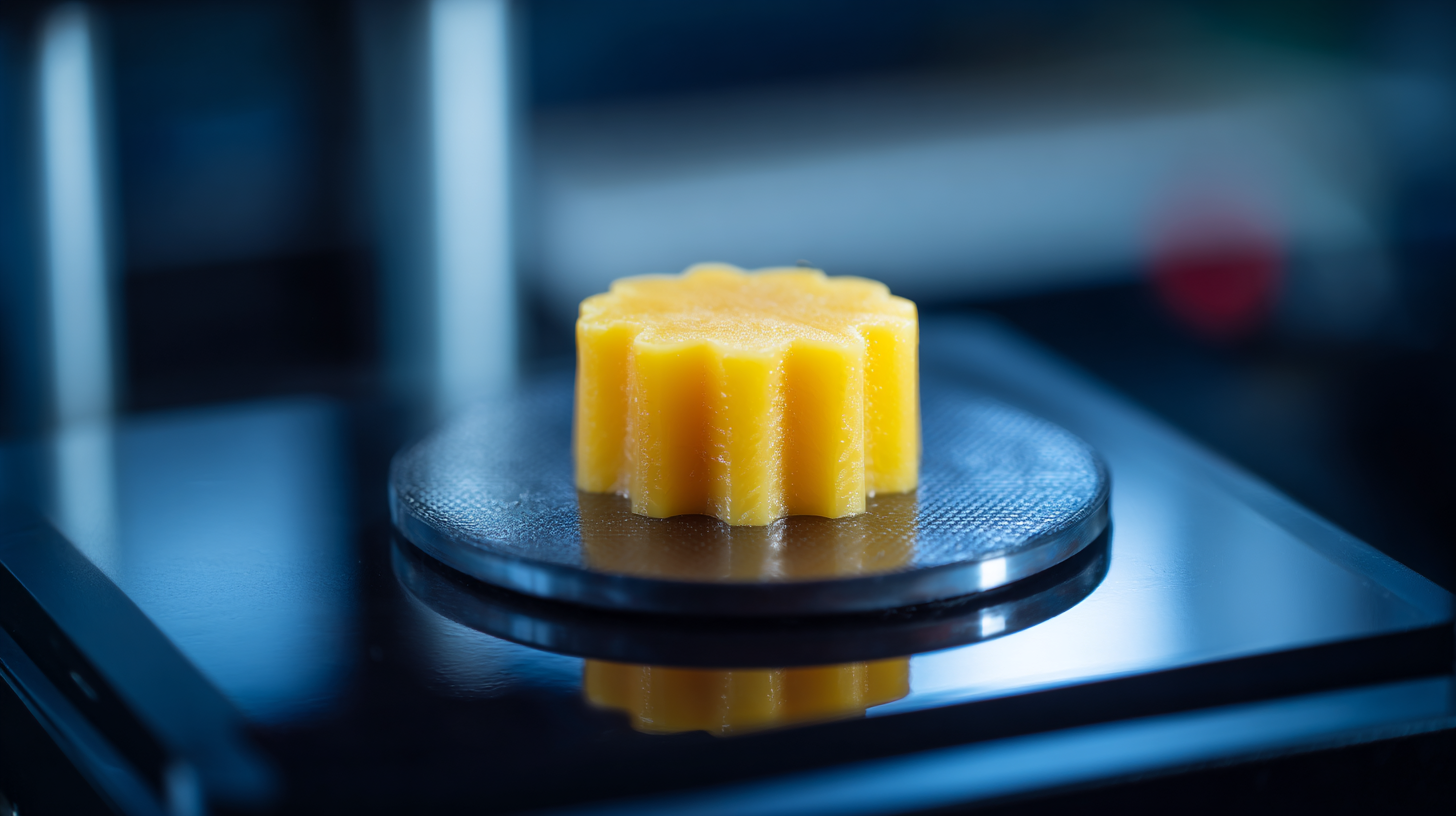

When utilizing high wax resin in 3D printing applications, it is essential to prioritize quality and compatibility with your printer. Start by selecting a resin specifically formulated for high detail and smooth finishes. This type of resin is particularly beneficial for creating intricate designs or patterns as it replicates fine details with precision. Always check the technical specifications of both your 3D printer and the resin to ensure they are compatible, as some printers may require specific types of wax resins for optimal performance.

Furthermore, proper handling and post-processing are crucial steps in maximizing the potential of high wax resin. Wear protective gloves and work in a well-ventilated area to minimize exposure to fumes. After printing, careful cleaning of the printed item is necessary, typically involving isopropyl alcohol to remove uncured resin. Post-curing under UV light also helps enhance the strength and detail of the print. Incorporating these best practices will lead to high-quality results while ensuring a safe and effective 3D printing experience.

| Feature | Description | Best Use Cases | Cost Range ($) |

|---|---|---|---|

| Viscosity | Low viscosity for detailed prints | Miniatures, jewelry, detailed parts | 50 - 100 |

| Curing Time | Fast curing for efficient production | Prototyping, short run production | 70 - 130 |

| Strength | High strength and durability | Functional parts, mechanical components | 100 - 200 |

| Surface Finish | Smooth finish for aesthetic applications | Art objects, display models | 80 - 150 |

| Color Options | Wide range of available colors | Custom designs, colorful prototyping | 60 - 120 |

When working with high wax resin in 3D printing, users may encounter various issues that can affect the quality of their prints. Common challenges include uneven curing, build adhesion failures, and defects in surface finish. According to industry reports, approximately 20% of 3D printing projects face failures due to issues with resin quality and settings. Proper calibration of your resin printer is crucial, as even slight deviations can lead to significant problems. Utilizing models specifically designed for testing resin printers can help identify and resolve these issues effectively.

Additionally, the selection of high wax resin plays a vital role in minimizing printing complications. High-quality resins often come with specific properties that enhance their usability for detailed applications, such as jewelry or dental modeling. It’s important to refer to the latest material guides, which suggest that bio-compatible and flame-resistant features are increasingly favored in 3D printing applications. Investing in high-grade wax resins not only improves print precision but also addresses common concerns that arise during the printing process, thereby streamlining the workflow for users at all levels of expertise.