Choosing the right Dental Resin 3D Printer is crucial for dental professionals. Dr. Sarah Johnson, a leading expert in dental technology, states, "The right printer can truly elevate your practice." With many options available, selecting the ideal printer requires careful consideration.

Factors such as build size, printing speed, and resin compatibility play significant roles. The market offers numerous models, each with unique benefits. However, not all printers perform equally in real-world scenarios. Dental practitioners must assess their specific needs.

It's essential to reflect on your workflow and patient demands. Are you focusing on crowns, bridges, or orthodontic models? Understanding your priorities can guide your decision. Selecting the best Dental Resin 3D Printer should enhance your efficiency and output quality. Avoid the common pitfalls of rash decisions based on trends.

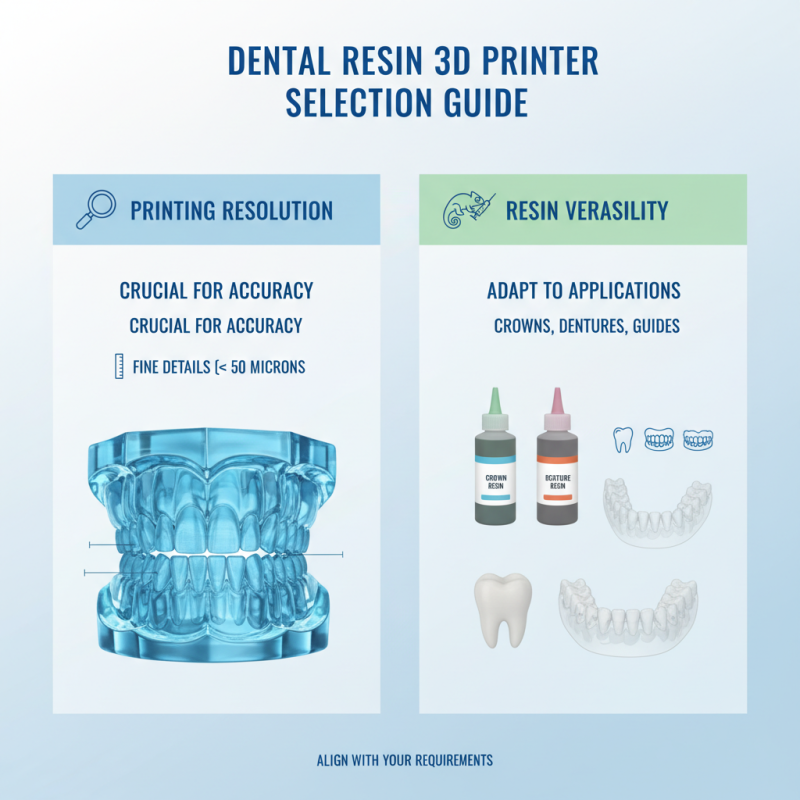

Choosing the right dental resin 3D printer requires careful consideration. One of the first factors to look at is the printer's resolution. High-resolution printers produce finer details. This is crucial for dental applications where precision matters most. Look for printers that can achieve layer thickness of 20 microns or less. The finer details lead to better fitting dental models.

Another critical factor is the build volume. A larger build volume allows you to print multiple items simultaneously. This can save time, especially in a busy dental practice. However, larger printers may require more space and can be more complex to operate. It's also essential to evaluate the ease of use. Some printers come with complicated software that can be challenging to navigate.

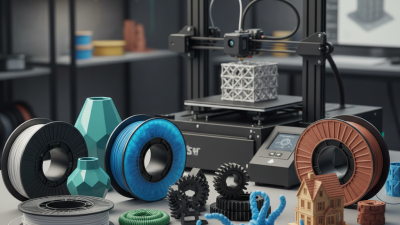

Material compatibility cannot be overlooked. Different dental applications require specific resins. Some are better for crowns, while others are suited for models or aligners. Make sure the printer you choose can handle a variety of materials. Lastly, consider customer support and community resources. A strong support system can help you troubleshoot issues that arise. It may be worth thinking about these aspects before making a hasty decision.

When selecting a dental resin 3D printer, it's essential to consider the types of dental resins available. Various resins serve distinct purposes, affecting their suitability for different applications. For instance, some resins are designed for creating crowns and bridges, showcasing remarkable strength and durability. Others might be more flexible, suitable for orthodontic applications. Each type has unique properties that can influence the final product's performance.

Understanding the characteristics of both rigid and flexible resins is crucial. Rigid resins offer higher precision and are ideal for models and prototypes. However, they may not handle stress as well as other materials. On the other hand, flexible resins are often employed for splints and retainers, providing comfort but possibly sacrificing some detail. It's vital to analyze how these differences align with specific dental needs.

Consider the post-processing requirements as well. Some resins necessitate extensive finishing, while others can be used directly after printing. This factor can impact workflow efficiency. As you weigh your options, reflect on your lab's unique demands and capabilities. Finding the right resin is less about the tech and more about understanding practical applications.

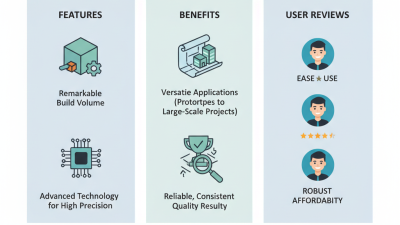

When selecting a dental resin 3D printer, consider key features that align with your requirements. Printing resolution is crucial. High-resolution printers yield finer details. This is essential for creating accurate dental models. Look for printers that can deliver resolutions under 50 microns. A printer that can handle different resin types is also beneficial. Versatility allows you to adapt to various dental applications, from crowns to dentures.

Speed is another factor that shouldn't be overlooked. Many dental labs work under tight deadlines. A faster printer can significantly boost productivity. However, ensure that speed doesn’t compromise print quality. Some models may sacrifice detail for quicker results. It’s important to assess if trade-offs are acceptable for your needs. Service and support options are vital, too. You might face technical issues or need maintenance. A responsive support service can save you time and frustration.

Lastly, consider the software compatibility. An intuitive interface with robust features simplifies the design process. If the software is complex, you may hesitate to fully utilize your printer's potential. User-friendly software enhances workflow and efficiency. Choose a printer that fits seamlessly into your current systems. Each choice has its pros and cons, requiring thoughtful consideration for optimal results.

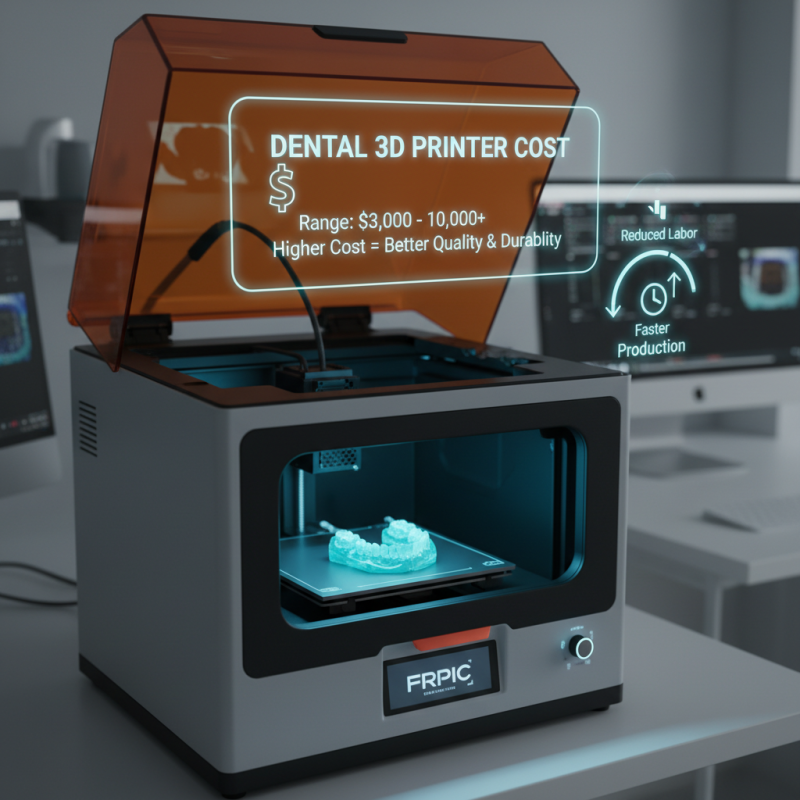

Investing in a dental resin 3D printer requires careful budgeting. The typical cost ranges from $3,000 to $10,000, depending on features and specifications. According to expert reports, a higher upfront cost often leads to better print quality and durability. Many dental professionals find that these printers pay for themselves over time due to reduced labor costs and faster production times.

Tips: Consider the total cost of ownership. This includes maintenance, materials, and software updates. Don’t just focus on purchase price. Lower-cost printers might have higher consumable costs. Think about your production volume. If you’re printing several items daily, a costlier printer with faster speeds may be worth it.

Be mindful of hidden expenses. Training staff for new equipment is crucial. A printer's initial price can mislead you. Think about your specific needs. Some printers excel in speed, others in precision. Balancing these factors is key for a successful purchase.

When evaluating print quality and precision in dental applications, several factors come into play. Resolution is key. High-resolution printers produce detailed models. You want to capture the fine details of dental structures. Layer thickness also matters. Thinner layers generally lead to smoother surfaces, but may increase printing time.

Another critical aspect is material compatibility. Different resins offer various properties like strength and flexibility. Some resins work better for crowns, while others are ideal for models. The printer’s performance can vary with each material. A mismatch can lead to fewer satisfactory prints.

Accuracy in fit is paramount in dental applications. Misfitting models can lead to issues in real-world applications. This is a crucial area for reflection. It’s essential to test print various designs and assess their fit. Regular calibration can improve precision. However, it’s not always foolproof. Printer settings might need constant adjustments to maintain quality. A balance of quality and efficiency is vital for success.