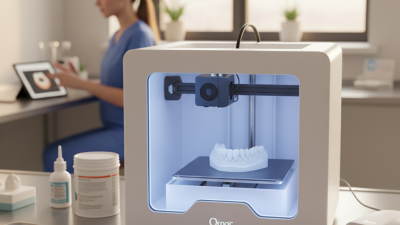

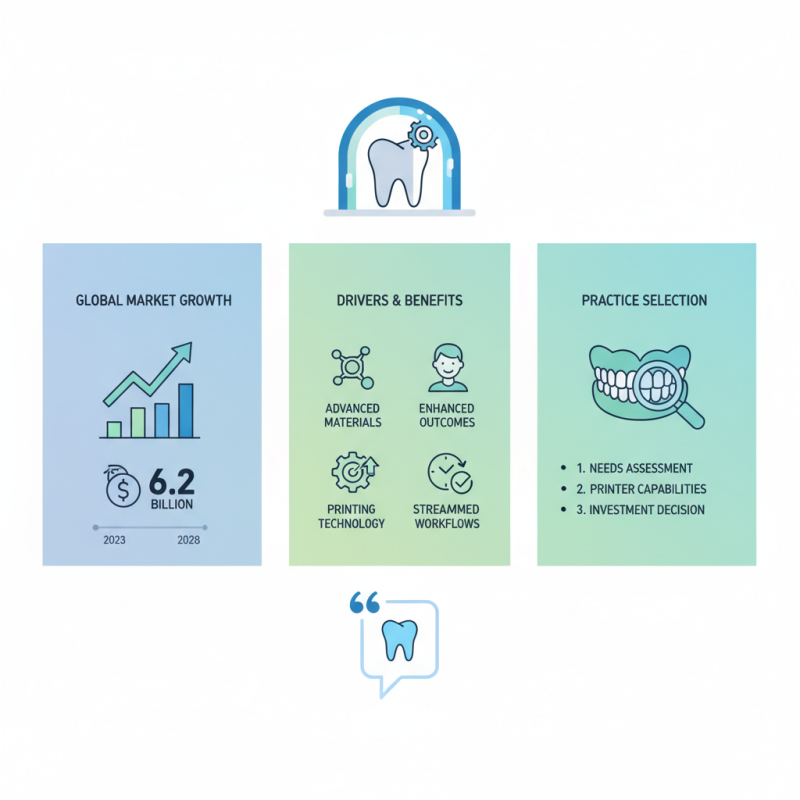

In the rapidly evolving landscape of dental technology, selecting the best Dental Resin 3D Printer for your practice is more crucial than ever. Recent industry reports indicate that the global dental 3D printing market is expected to reach $6.2 billion by 2028, driven by advancements in materials and printing technology. As practitioners seek to enhance patient outcomes and streamline workflows, the demand for high-quality dental resin printers has surged, promising unprecedented levels of precision and efficiency in dental restorations and prosthetics.

Dr. Emily Thompson, a leading expert in dental manufacturing technology, emphasizes the importance of choosing the right tools for dental practices, stating, "The efficiency and accuracy of a Dental Resin 3D Printer can significantly affect the quality of dental restorations, distinguishing practices in a competitive market." This insight highlights the necessity for practitioners to remain informed about developments and capabilities in dental resin technology as they make investment decisions. With a wealth of options available, understanding the specific needs of your practice and aligning them with the capabilities of varying printers is essential for maximizing the benefits of this transformative technology.

Dental resin 3D printing technology has revolutionized the field of dentistry by enabling the creation of high-precision dental models, crowns, and other prosthetics. This additive manufacturing process utilizes photopolymer resins that are cured layer by layer using ultraviolet (UV) light, yielding intricate designs that can closely mimic the natural anatomy of teeth. The ability to produce customized dental solutions in a shorter timeframe not only enhances patient satisfaction but also improves the efficiency of dental practices.

Applications of dental resin 3D printing are diverse and continuously expanding. In orthodontics, for instance, it facilitates the production of clear aligners and custom retainers that offer superior comfort and aesthetic appeal. Additionally, dental laboratories leverage this technology to fabricate surgical guides, dentures, and indirect restorations with remarkable accuracy. As the technology evolves, practitioners can expect advancements that will further enhance the quality of care they provide, making it essential to stay informed about the latest developments in dental resin materials and printing techniques.

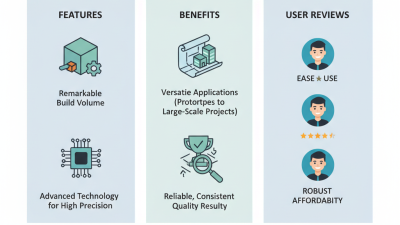

When selecting the best dental resin 3D printer for your practice, several key features should be considered to ensure optimal performance and efficiency. One of the most critical factors is build size, which determines the maximum dimensions of the objects you can produce in one print. Depending on your needs for creating dental models, crowns, or aligners, a larger build size may be necessary to accommodate different patient requirements. Additionally, print resolution is essential; higher resolution allows for more intricate details and smoother finishes, which are crucial in achieving the precision needed for dental applications.

Another important feature to evaluate is the printer's speed. In a busy dental practice, turnaround time is vital. A faster printer will enable you to produce high-quality models in less time, allowing for more efficient workflow and better patient service. Furthermore, consider the material compatibility of the printer. Different dental resins are available for various applications, so choosing a printer that can work with a wide range of materials will enhance your practice’s versatility. Lastly, ease of use and software compatibility are factors that should not be overlooked; a user-friendly interface and robust software can significantly reduce the learning curve and ensure seamless integration into your existing workflows.

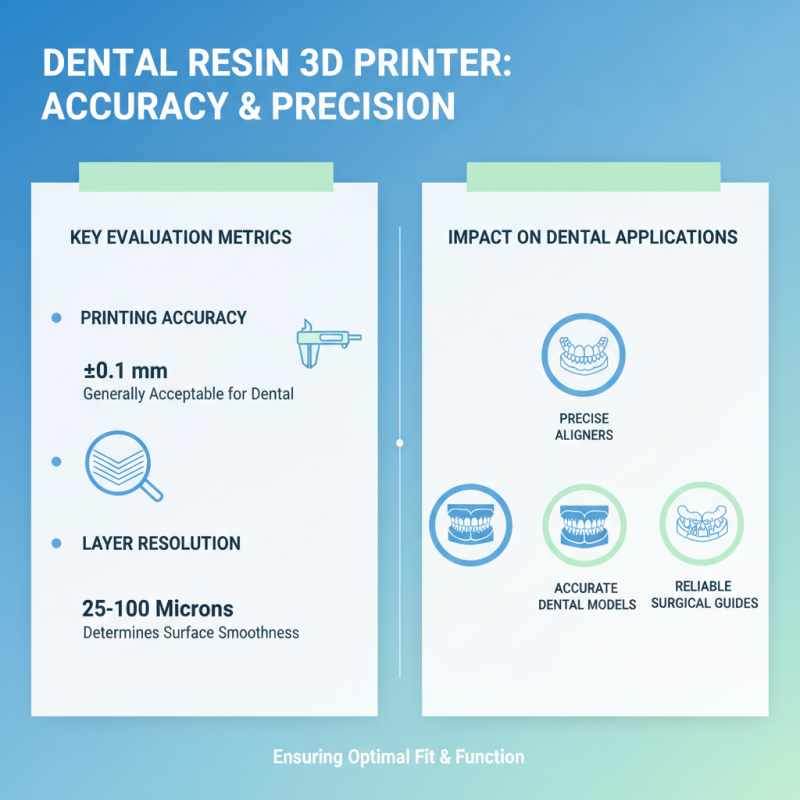

When considering a dental resin 3D printer for your practice, evaluating the accuracy and precision of these devices is crucial. Reports from industry leaders indicate that a printing accuracy within ±0.1 mm is generally acceptable for dental applications, ensuring that the final products adhere to stringent fit and function requirements. Additionally, layer resolution, which typically ranges from 25 to 100 microns, plays a significant role in determining the quality of the prints. Higher resolutions lead to smoother surfaces and finer details, essential for producing precise dental models, aligners, or surgical guides.

Tips: When selecting a 3D printer, always look for devices that offer calibration features. Regular calibration helps maintain accuracy over time, ensuring that all printed parts meet the necessary specifications. Moreover, consider a machine that uses a dual-light projection system, which has been shown to enhance precision and reduce printing errors significantly.

Furthermore, the printer's ability to handle various materials contributes to its versatility. A study published in the Journal of Dental Research highlighted that printers capable of utilizing multiple resin types allow for a broader range of applications, from rigid structures to flexible materials, thus catering to diverse clinical needs. Always ensure that your chosen printer can effectively process the resins specific to your applications while maintaining the accuracy required for high-quality dental restorations.

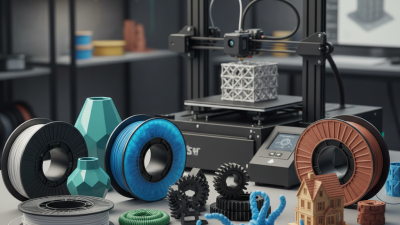

When selecting a dental resin for 3D printing, compatibility with your specific printer and the intended dental applications is paramount. Different resins exhibit varying physical and chemical properties, influencing factors such as print accuracy, surface finish, and mechanical strength. For instance, some resins are engineered to meet the rigorous demands of dental restorations, providing durability and a natural aesthetic, while others might cater to temporary applications where rapid prototyping is essential. Understanding the characteristics of each resin type will help practitioners choose the best material for their intended uses.

Performance is another critical factor to consider when comparing dental resins. Resins can differ significantly in terms of biocompatibility, ease of post-processing, and resistance to wear and tear. A resin that performs well in one application may not meet the requirements of another, especially in terms of stress and strain during use. Additionally, the curing times and required equipment for finishing can vary, which might impact the overall workflow in a dental practice. Careful evaluation of these performance aspects will enable dental professionals to make informed decisions that enhance treatment outcomes and patient satisfaction.

When considering the integration of dental resin 3D printers into a practice, assessing cost-effectiveness and return on investment (ROI) is crucial. The initial investment in a 3D printer can be significant; however, practices must analyze how it fits into their broader financial goals. Evaluating the upfront costs against potential savings in labor and materials over time can provide a clearer picture of overall financial viability. A well-chosen printer can streamline workflows, reduce production time, and minimize the need for outsourcing, all of which contribute positively to the practice's bottom line.

Moreover, the return on investment in 3D printing can be enhanced by evaluating the range of applications available. From creating dental models to producing surgical guides and custom prosthetics, the versatility of dental resin printers means they can serve multiple purposes within a practice. By calculating the potential revenue generated from in-house production versus the cost of outsourced manufacturing, dentists can make informed decisions about the best printer to meet their needs. Ultimately, a focus on both cost-effectiveness and potential for revenue generation will guide practices in selecting technology that not only enhances patient care but also supports financial growth.